Short-Distance Flow Straightening Technology

Technology at Japan Wind Tunnel Mfg.

Japan Wind Tunnel Manufacturing has the advantage of "short-distance flow-straightening technology" that creates a uniform and turbulence-free airflow within a short distance. This allows us to produce compact products such as the Aero Optim series as well as to manufacture conventional large wind tunnels that are shorter and more energy-efficient.

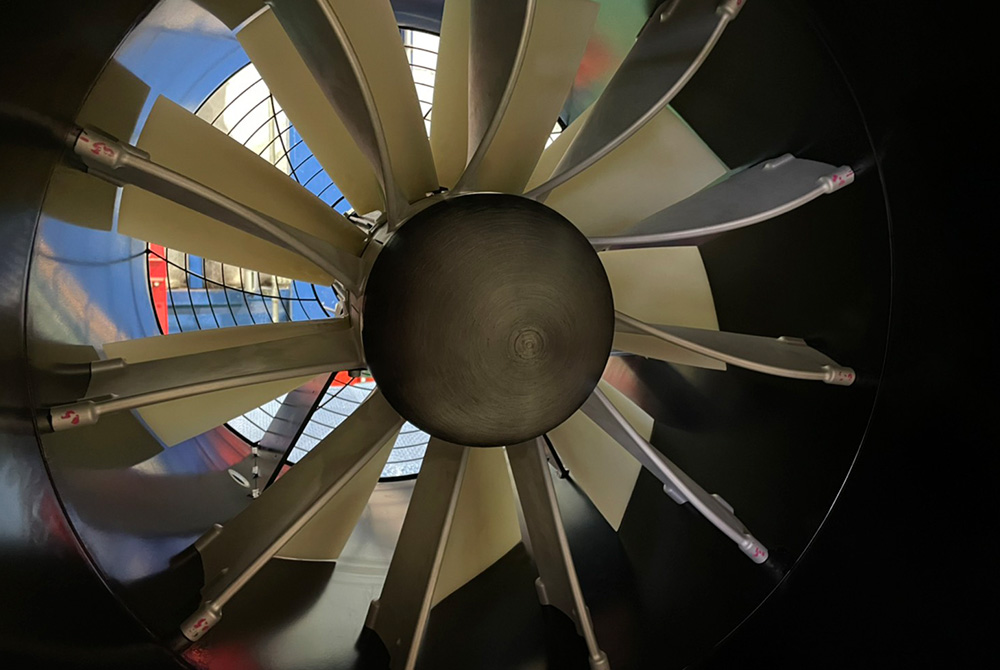

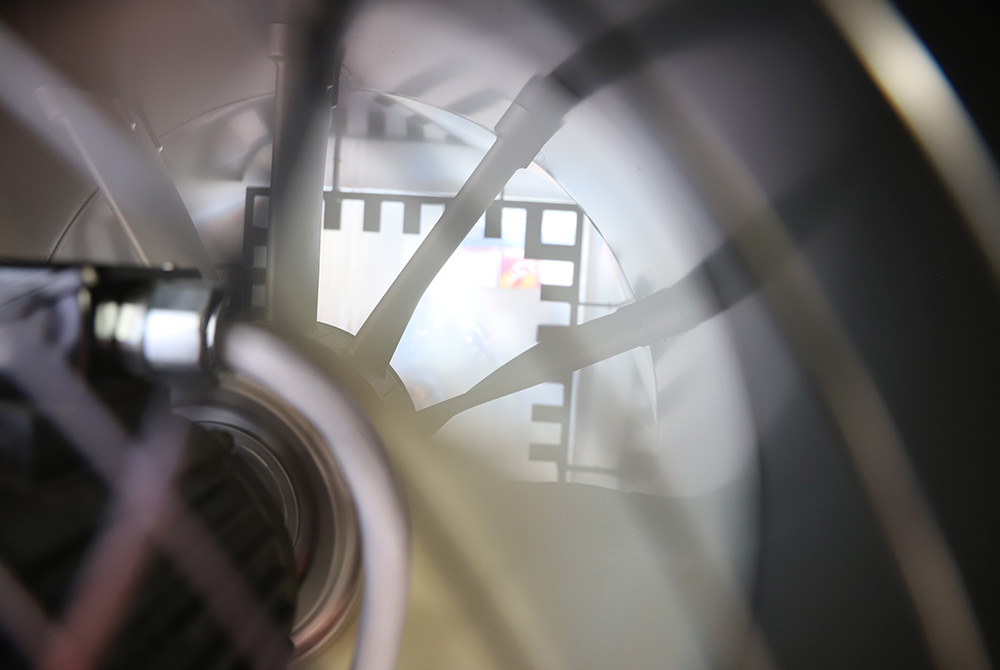

The Aero Optim series wind tunnel unit is only 1.4 meters long. Conventional models generally require 20m to several hundred meters in length. Normally, in order to straighten the airflow over such a short distance, enormous energy is required, and the required size of the fan becomes larger. Therefore, the flow-straightening methods used in conventional wind tunnels were not compatible with a cube-shaped, stackable wind tunnel concept. After eight generations of prototyping and hundreds of trials, we have developed a unique distortion screen and guide vane technology that has not been seen in conventional wind tunnels. This was done by adopting technology methods used in military jet and rocket engines. The technology allows us to fit the entire function of a wind tunnel into this package. This highly efficient flow-straightening technology is now also utilized in our large wind tunnels and other wind tunnels that we design, which are generally more energy efficient.